Every dentist has their own necessary set of instruments without which they cannot perform their work. One of these instruments is the dental bur. These are connected to advanced machines that allow for rotational movement. This movement is necessary for a wide variety of applications and procedures in the world of dentistry. Here are several important facts about dental burs.

Table of Contents

Uses of Dental Burs

As mentioned, dental burs can be used in several different procedures, be they simple or complicated. Their basic function is to cut different types of hard tissues, such as bones and teeth. This ability is important for the dentist in many different situations. These include complicated surgeries, preparation for mechanical retentions, cavity creation, and much more.

Naturally, each bur’s function differs because of several factors. These mainly include bur types, bur shapes, and the materials from which the burs are made. Some bur types can even be compatible for work with animals as well as humans, making them quite versatile.

Different Types of Burs by Speed

There are two main types of Dental burs indicated by their speed which are commonly found throughout clinics: Low speed and High speed (turbine) burs. Low – speed burs are either air – driven or electric – driven by a handpiece. Low – speed burs are designed to handle more air pressure compared to high – speed burs. They are often useful for the removal of caries, refining cavity preparation, and other endodontic procedures.

High – speed dental burs are often used for surgical procedures. They function similarly in principle to the low – speed variant but are used for different procedures. These include cavity preparation, removal of tooth structure, and margin creation.

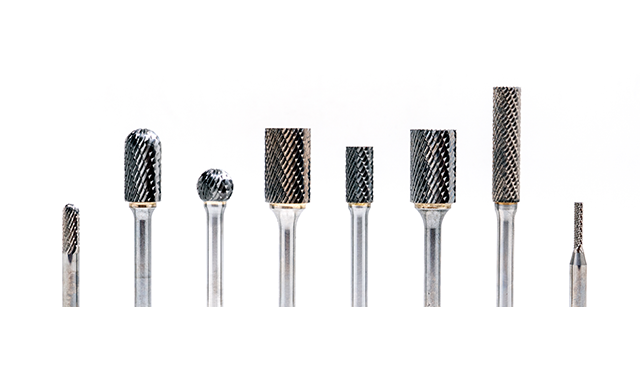

Dental Burs by Shape

There are many different shapes of dental burs, each defining the bur’s role and available procedures to be used with it. One of the is the round bur. They can be used for many different procedures. Cavity preparation, opening teeth for endodontic treatment, cleaning the tooth from caries, selective grinding, and bone surgery are among the most common procedures.

Pear – shaped burs are similar to round burs but feature an elongated form. Their main usage is found in restorative work, especially when retention is needed as part of cavity creation. This type of bur can also be used for the removal of caries, trimming, and finishing of dental tissues.

Another shape type of dental burs is a straight fissure bur. These have parallel lines that move diagonally in relation to the head itself. Their main use is in the creation of parallel lines and flat floors as part of treatments. This action is particularly desirable in procedures such as wall forming during cavity preparation and placement of retention grooves.

Different Materials Used in Burs

The different materials used in the manufacturing of burs also dictate its role. Ceramic burs for example are especially suitable for dealing with sensitive environments in the mouth. Their heat conduction properties prevent them from overheating too easily. Because of this, they are most useful for the modification of acrylic parts whilst performing dental surgeries.

Burs made of steel are one of the most common choices in dental medicine. Their lack of rigidity, as well as their low price and the variety of shapes and textures they come with, makes them a popular tool. They are most often used for cavity preparation, dentine removal, preparation of crowns, as well as multiple other dental procedures.

Carbide dental burs are burs made of carbide, an alloy containing both carbon and tungsten. This alloy gives the bur increased robustness over regular steel burs. As such, it is often employed in situations where extra strength is required. These include cavity preparation, cutting through metal fillings and teeth, and bone splitting during implant surgeries.

Gold – plated burs are especially ideal in circumstances where smoothing actions are required. They work with fewer vibrations which allows for a higher level of local precision to be achieved during work. This makes them ideal for procedures where extreme precision is needed. On top of that, they do not heat up as much as other metals, thus maintaining teeth vitality.

Lastly, Diamond Burs. These are made primarily of stainless steel but are additionally coated with a diamond powder at their tips. This naturally gives a high level of grit, allowing very smooth finishes to be applied on the teeth’s surfaces. Since diamond is the hardest natural substance on earth, the finishes can be applied with ease.

Conclusion

Burs come in a wide variety of shapes and materials, making them an extremely versatile tool. This resulted in near-universal dependence on them by dentists and dental lab workers in their work. If one wishes to acquire dental burs, one should know which types to choose as well as where to choose them from.